LASER MARKING SYSTEMS

the BEST LASER MARKING SYSTEMS ON THE MARKET

HIGH VALUE, HIGH ROI, INDUSTRIAL GRADE SYSTEMS

CUSTOM OR STANDARD

AUTOMATED OR MANUAL

METALS, PLASTICS, & ORGANICS

fulgamut, Inc is a laser marking machine supplier that offers great solutions for laser marking equipment. Our laser marking systems for sale are available in a number of formats:

OEM versions are configured so you can integrate them into an existing system or production line. The consist of everything you need to mark product in your own integration.

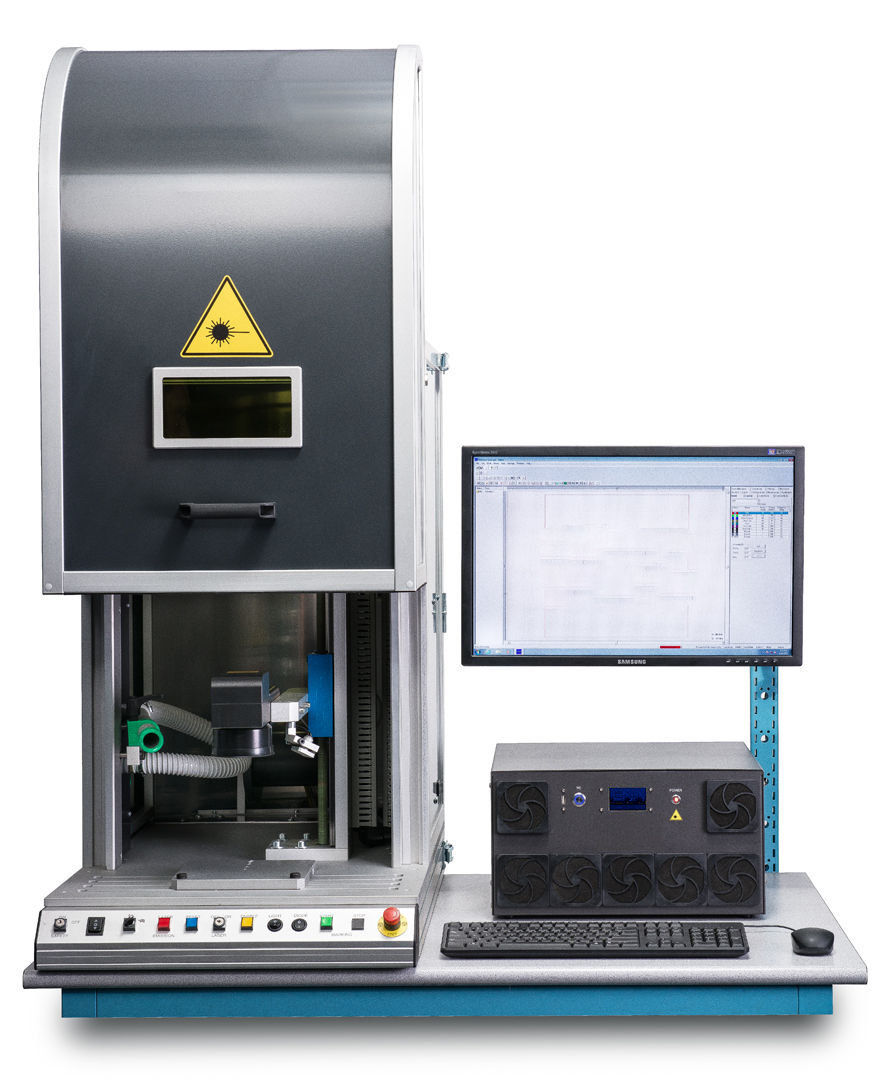

Standard Class I enclosures with manual load unload, for small or medium volume capability. These systems can also be configured with X, Y motion, or two position rotary tables for continuous processing if desired, and they all come with a programmable Z axis. It is also possible to equip them with machine vision for finding a fiducial for example, for alignment, or other features.

Fully automated work cells with in-feed and out-feed, utilizing factory automation pallets, custom tooling or robotics. The machines can be linked to your factory automation if you so require.

These laser marking systems are fiber laser based, in a variety of power levels, as well as with a CO2 laser source for those materials requiring the longer wavelength. Ultra-short pulse lasers are available if the application requires it, and the budget will support that increase in cost.

These industrial laser marking machines have been sold all over the world and installed in many different circumstances, from advanced technology centers to mom-and-pop operations. These tabletop and roll-around base laser markers are extremely robust and flexible, so they will put up with environments from the back shop to the clean room.

These fiber laser marking machines will mark on all metals and most plastics.

When using these laser marking systems, laser marking is accomplished in three easy steps.

Focus the laser onto the part

Select or create your mark

Mark your part

The major components of the system include the Laser Control Unit with a touch screen display and embedded PC, the fiber laser which is essentially maintenance free with a meantime between failure of over one hundred thousand hours, and the enclosure which houses the laser marking head, integrated fume extractor hose and motorized or programmable z-axis to easily accommodate different part heights with over 14 inches of travel.

These laser marking systems also provide the largest work area in their class and are interlocked for laser safe operation. Focusing onto the part couldn’t be easier with our integrated red beam focusing aid. Simply adjust the z-axis to position the dot in the box.

The software is intuitive, with a variety of powerful features. You can import a wide range of image files-vector or raster. It has its own text editor and the ability to generate one-D or two-D barcodes with serialization. The system can be manually operated or integrated into your factory controls through, serial, digital I/O or PLC.

Click on the Gallery below to see systems and marking samples.

![White_Polycarbonate[1].jpg](https://images.squarespace-cdn.com/content/v1/51d5149ce4b07e302339da73/1516392426718-8X0MQW1X3YRM591CK5OJ/White_Polycarbonate%5B1%5D.jpg)

![Deep_Engraving_On_Curved_Surface[1].jpg](https://images.squarespace-cdn.com/content/v1/51d5149ce4b07e302339da73/1516392458760-YKJKT3LJUE5YATGAQ1WU/Deep_Engraving_On_Curved_Surface%5B1%5D.jpg)

![Ablation[1].jpg](https://images.squarespace-cdn.com/content/v1/51d5149ce4b07e302339da73/1516392513429-BGLA2IXFH9TG5Y4F5JRL/Ablation%5B1%5D.jpg)

![Dwyer-Brass[1].jpg](https://images.squarespace-cdn.com/content/v1/51d5149ce4b07e302339da73/1516392601827-2VXY76G6P4NGOSSVOFM1/Dwyer-Brass%5B1%5D.jpg)

![US_Ordnance_2[1].JPG](https://images.squarespace-cdn.com/content/v1/51d5149ce4b07e302339da73/1516392679179-1HHFY1OS9KEGMLIWP8DQ/US_Ordnance_2%5B1%5D.JPG)

![AEI_CEL_BARCODE[1].jpg](https://images.squarespace-cdn.com/content/v1/51d5149ce4b07e302339da73/1516392738772-8OOS4YKOXKEHX9TFO70V/AEI_CEL_BARCODE%5B1%5D.jpg)

![Form_Roll[1].jpg](https://images.squarespace-cdn.com/content/v1/51d5149ce4b07e302339da73/1516392724471-P6XWF3E3MS4FPRRJ8Q1T/Form_Roll%5B1%5D.jpg)

![Dynabrade_4[1].jpg](https://images.squarespace-cdn.com/content/v1/51d5149ce4b07e302339da73/1516392572593-UWT0ZQZRFXXW4UHQVEO1/Dynabrade_4%5B1%5D.jpg)